Last Updated on: March/20/2018 |

for 1024x768 & higher screen resolution |

Telephone:+1(774)929-7084 |

| >Downloads>SAE J1939 Simulator Gen II |

User Manual for

Au SAE J1939 Simulator-Gen II Ver 1.00A (simplified edition)

|

Push Button Operation |

Function |

Press DOWN button |

Decrease all simulated data until it reaches the lowest value |

Press UP button |

Increase all simulated data until it reaches the highest value |

Press MENU button |

DM1 Warning On/Off control (N.A. for Engine Basic Edition(s)) |

Press and hold MENU button when power on |

Simulator will enter Bootloader mode, if no communication is detected from a PC Bootloader program within 10 seconds, it will resume normal mode |

Press and hold both DOWN + UP button |

Buzzer ON/OFF control |

Press and hold both MENU + UP button |

Switch between Static/dynamic mode |

Press and hold both MENU + DOWN button |

Engine DM2 ON/Reset control (N.A. in Engine Basic Edition) |

AU J1939 SIMULATOR REMOTE TERMINAL

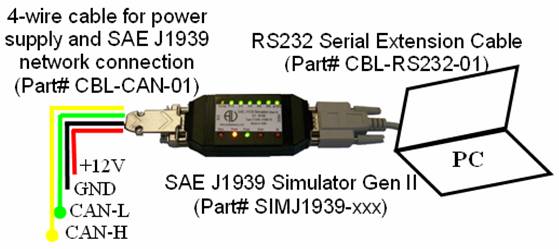

All Au J1939 Simulator editions can be easily integrated into a SAE-J1939 network (with a 4-wire cable). And all PLUS editions can be connected to a PC (with a RS232extension cable), as shown in figure 4.

Figure 4 – Typical PC and network Connection of Au SAE-J1939 Simulator

The 4-wire cable (which has a DB9 connector on one end, a pigtail on the other end, can be ordered seperately with Au Part # CBL-CAN-01) for power supply and SAE-J1939 network connection is color coded as shown in table 2.

Table 2 - Color code of 4-wire cable

Color |

Signal |

Red: |

+12 V power supply |

White: |

CAN-H |

Green: |

CAN-L |

Black: |

Ground |

Au J1939 Simulator Remote Terminal is available for all Au J1939 Simulator PLUS editions. It is designed for displaying detail information on all simulated SAE-J1939 signal. The interface includes a control panel and a display panel. The control panel is located in the up-left corner. all the other area display info like engine/ABS/Transmission info, warning lamp, etc. as shown in figure 5 - 1, 5 - 2, 5 - 3.

Figure 5 -1 shows the J1939 Simulator Remote Terminal GUI (Graphic User Interface) for vehicle platinum plus edition. All features are active.

Figure 5 - 1 - Au J1939 Simulator Remote Terminal GUI – Vehicle Platinum Plus

Figure 5 -2 shows the J1939 Simulator Remote Terminal GUI for Engine Premium Plus edition. Engine info and warning lamps, engine basic parameters, engine DM1, and engine DM2 are available. ABS info, Transmission info and engine configuration are not available.

Figure 5 - 2 - Au J1939 Simulator Remote Terminal GUI – Engine Premium Plus

Figure 5 -3 shows the J1939 Simulator Remote Terminal GUI for Engine Basic Plus edition. Engine info and Cruise lamps, engine basic parameters are active for this edition.

ABS info, Transmission info, engine DM1, engine DM2, and engine configuration are not available.

Figure 5 - 3 - Au J1939 Simulator Remote Terminal GUI – Engine Basic Plus

- Display Panel – Engine Basic Parameters

Display the following 16 engine basic parameters: Engine Speed(RPM), Engine hour (Hr), Vehicle speed (MPH), Engine oil pressure (PSI), Engine coolant temperature (F), Battery voltage (V), Fuel level (%), Engine boost pressure (PSI), instant fuel economy (MPG), instant fuel rate (GPH), accelerator position (%), inlet air temperature (F), engine load percentage (%), engine trip (mile), total vehicle distance (mile), and engine clock (HH:MM) (figure 6).

Note: Engine Clock is not controlled by the control step value, it runs by itself like a real clock, and can be setup by PGN 54528.

Figure 6- Display panel – Engine basic parameters

- Display Panel – Engine DM1

Engine DM1 message could be one packet (without warning or with 1 warning) or multi-packet.

If engine DM1is a single packet, SPN, FMI, OC, CM will display (figure 7-1). If engine DM1 is a multi-packet, "see @ Multi-Packets" will display, “Multi-packets” button will be active (figure 7 – 2), click on it, the whole list of engine DM1 will display. If Engine DM1 or DM2 warning is off, a SAE defined non-warning message will be shown as (0,0,0,0).

Figure 7 -1- Engine DM1 Single Packet Figure 7 - 2 - Engine DM1 Multi-Packet

- Display Panel – Engine DM2

Engine DM2 message could be one packet or multi-packet. If engine DM2 is a single packet, SPN, FMI, OC, CM will display (figure 8-1). If engine DM2 is a multi-packet, "see @ Multi-Packets" will display, “Multi-packets” button will be active (figure 8–2), click on it, the whole list of engine DM2 will display.

Figure 8 -1- Engine DM2 Single Packet Figure 8 - 2 - Engine DM2 Multi-Packet

- Display Panel – Engine Configuration

Engine Configuration PGN includes 34 bytes of messages which require transport protocol for multi-packet communication. “Engine Configuration” button will be active on the GUI (Figure 9 -1) for vehicle platinum edition(s).

Figure 9 -1 - Display panel – Engine Configuration

- Display Panel – ABS DM1

ABS DM1 is a single-packet PGN. If ABS warning is off, a SAE defined non-warning message will be shown as (0,0,0,0); If ABS warning is on, a Brake Switch signal low warning will be shown (597,1,7,0) (figure 10).

Figure 10- Display panel – ABS DM1

- Display Panel – Transmission DM1

Transmission DM1 is a single-packet PGN. If transmission warning is off, a SAE defined non-warning message will be shown as (0, 0, 0, 0); if the warning is on, a transmission oil warning will be shown as (177, 0, 126, 0) (figure 11).

Figure 11- Display panel – Transmission DM1

As defined by SAE-J1939/21, the Au SAE-J1939 simulator response to different “engine DM2 request” with different transport protocols (illustrated in Table 3).

Table 3 – Transport Protocol for DM2 global/specific request

Request |

Transport Protocol |

Global request |

TP.CM.BAM |

TP.DT |

|

Specific request |

TP.CM.RTS |

TP.CM.CTS |

|

TP.DT |

|

TP.CM.EndOfMsgACK |

|

TP.CM.Abort |